About Us

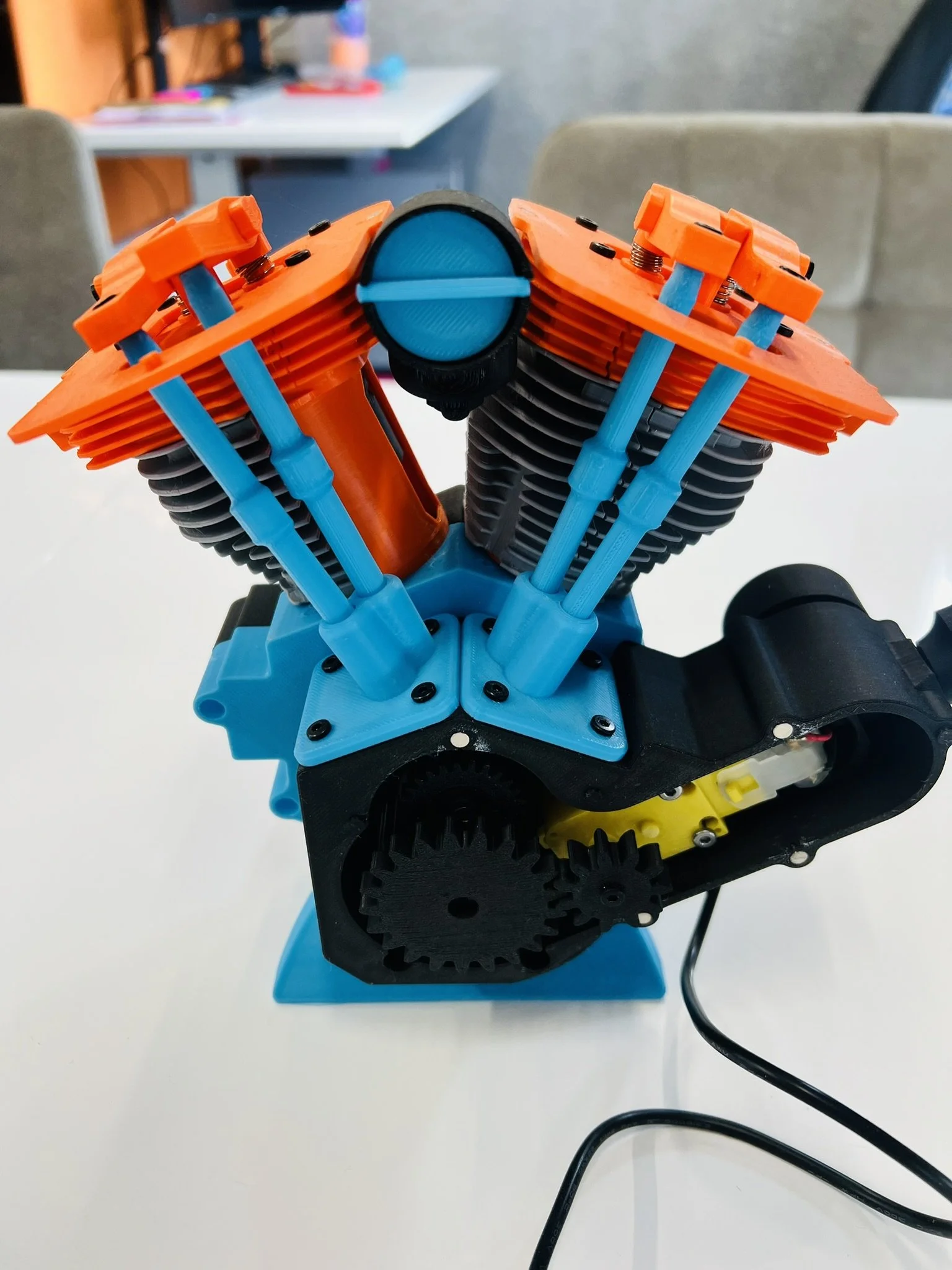

Having worked with 3D printing since its early, challenging days, we've developed the skills and techniques to produce not only high-quality results but also durable and innovative solutions. By applying our background in engineering and construction, we enhance parts through strategic use of materials, infill density, and print orientation—skills that come from years of experience and a deep understanding of the technology.

We regularly print our own parts and products, so we understand the importance of high-quality finishes and the realistic limitations of 3D printing. This knowledge helps us manage expectations and deliver optimal results.

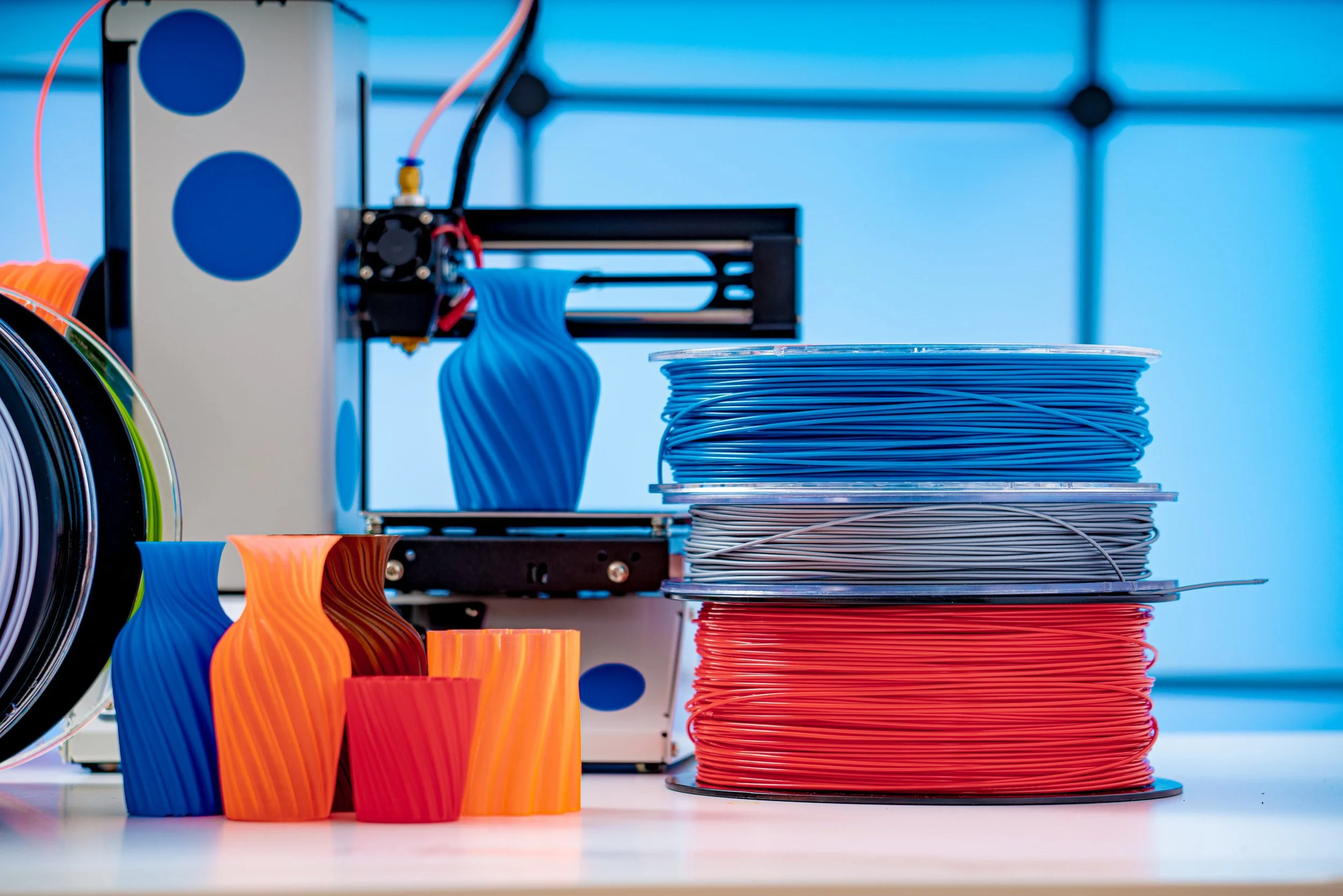

Our equipment features the latest top-tier 3D printing technology, including four machines that handle various filament types. This includes closed-chamber Core XY systems and bedslingers, giving us versatility across projects.

We offer a wide variety of 1.6mm filament options, from polylactic materials to engineering plastics like PLA, PLA+, PETG, TPU, and ASA. Plus, we have an extensive range of color options to bring your designs to life.

Our process starts with your CAD file (STL, STP, or 3MF). After discussing your desired finish, we slice the model using advanced software, dial in strength and finish profiles, select the appropriate material, and, finally, choose the perfect color. Then, we get to printing!

See some of our work below!

Top quality NZ Made Filament

As a proud Kiwi company, we are thrilled to partner with KiwiFil as our preferred supplier for PLA+ and PETG filament. Their high-quality materials, crafted with precision and passion, are made right here in New Zealand. KiwiFil produces both virgin and 100% recycled filament, and they go the extra mile by offsetting 1.4 kg of CO2 for every 1 kg spool sold, through Gold Standard certified programs.

Colour Options

With so many color options available, which can vary depending on the material type, it's best to discuss your project with us first. However, to give you an idea of the color range, click here:

3D Printing Design Guidelines

These simple guidelines will help you get started with designing for 3D printing. When creating a part, keep these key factors in mind: Printability, Strength, Finish, Cost-effectiveness.

Size and Orientation

Our largest print size is 450 x 450 x 470mm. For larger parts, we can print them in sections and assemble them afterward.

Solid Surfaces

All printed surfaces must be solid and closed. Thin walls should be at least 1mm thick.

Accuracy and Resolution

Our printers can achieve the following layer heights: FDM: 0.2-0.4mm. Smaller, complex parts benefit from fine resolutions, while larger parts are more economical at 0.1-0.4mm. Tolerances vary from +/-0.05mm to 0.5mm based on part size and complexity.

Clearances

Here’s a simple guide for fitting parts: 0.1mm: Tight fit, 0.2mm: Smooth sliding fit, 0.3mm: Loose fit.

Fillets and Radii

Fillets (rounded edges) aren’t required but offer several advantages being improved strength, less support material and a better finish.

Overhangs and Support Material

Some parts need support material during printing. To minimize this, try: Reducing horizontal flat surfaces. Using angles between 40-90 degrees, which typically don't need support, positioning of flat surfaces on the bottom.

However do not be concerned with the above, most of the time we can fine tune the CAD file for you and we will slice the file using our software for printing so wall thicknesses, infill density and resolution can be dialed in at our end —we’ll make sure your print turns out perfectly!